Although electric vehicles have demonstrated their viability in the face of gasoline, manufacturers are trying in every way to improve batteries so that they are both more efficient, longer lasting, less expensive to produce and above all, less polluting during their time. Architecture promising more autonomy to users.

One of the most important advances in battery evolution is development and commercialization LFP batteries To replace lithium-ion batteries, it currently powers the vast majority of electric vehicles on our roads.

What is an LFP battery?

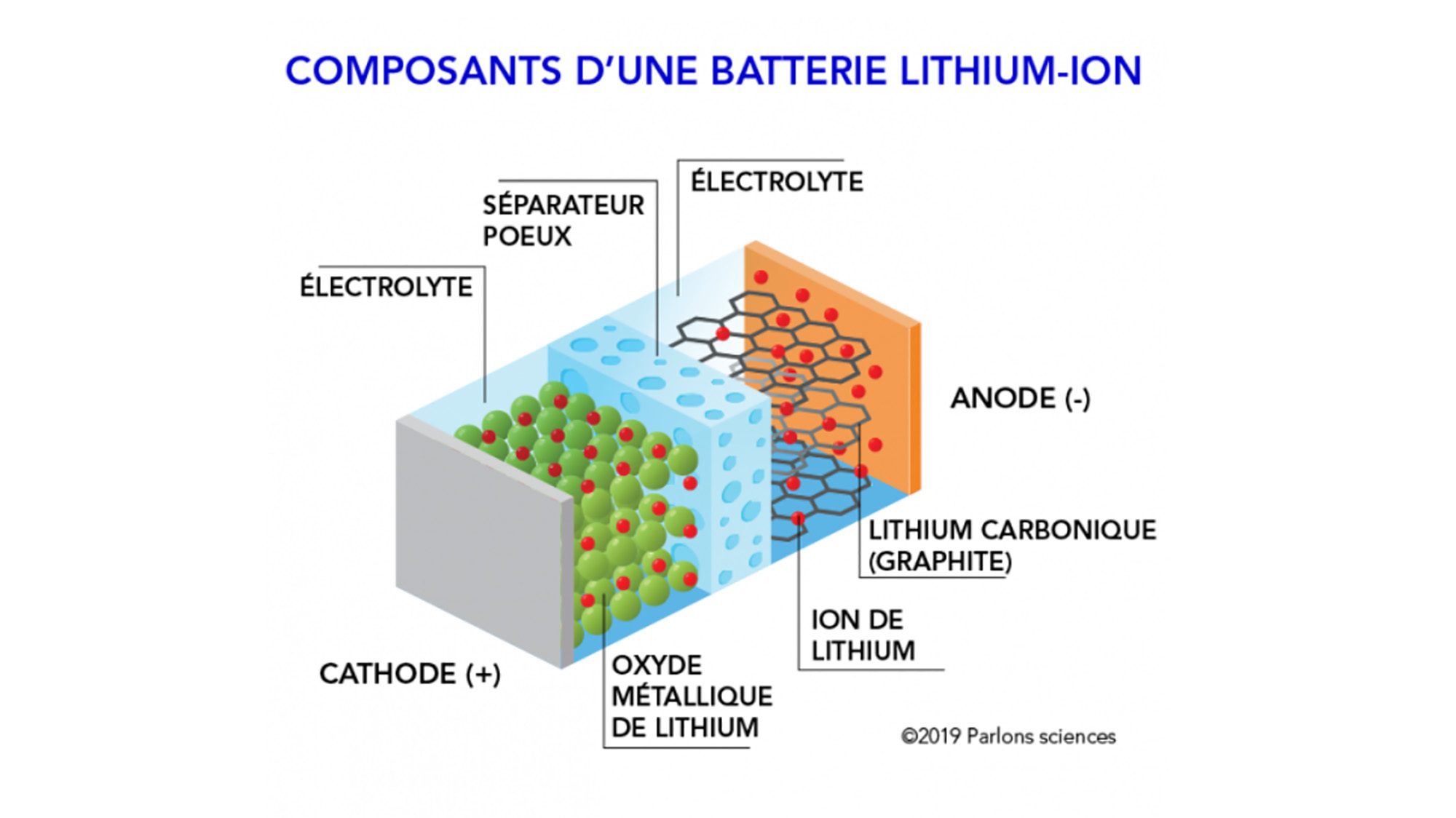

Abbreviation of LFP Lithium-Iron-Phosphate (In English, also known as lithium iron phosphate, chemical term LiFePO4). These terms describe the battery’s chemical composition, which is different from a typical lithium-ion battery.

Early attempts to use cells LiFePO4 The composition of the battery dates back to 1996. Padhi et al, a chemical engineer at the Electrochemical Society (EMS) in New Jersey, made this first discovery.

However, he found that LiFePO4 cells had very low electrical conductivity and hindered the marketing of the LFP battery. The consensus at the time was that this type of battery could not compete with the energy density of a lithium-ion battery.

However, French scientist and professor Michel Armand, a former employee of Hydro-Québec, with the help of his colleagues, realized that if he added carbon nanotubes to LiFePO cells and reduced their particle size, it would. It is possible to overcome conductivity problems.

Other researchers such as Yet-Ming Chiang, a chemical engineer of Taiwanese origin, also worked on the development of LFP batteries. He came up with the idea of using a doping process for semiconductors that would help increase the conductivity of the LFP battery.

Which electric cars have an LFP battery?

Today, the LFP battery is experiencing a resurgence in popularity, due to major manufacturers’ interest in making batteries for their low-cost electric vehicles. Tesla is also the first manufacturer to implement it in the Model 3 in 2021, while other manufacturers such as Mercedes-Benz and Ford are considering switching to this type of battery. It was the interest of the main manufacturers that prompted the development of this type of battery.

How does an LFP battery perform compared to a lithium-ion battery?

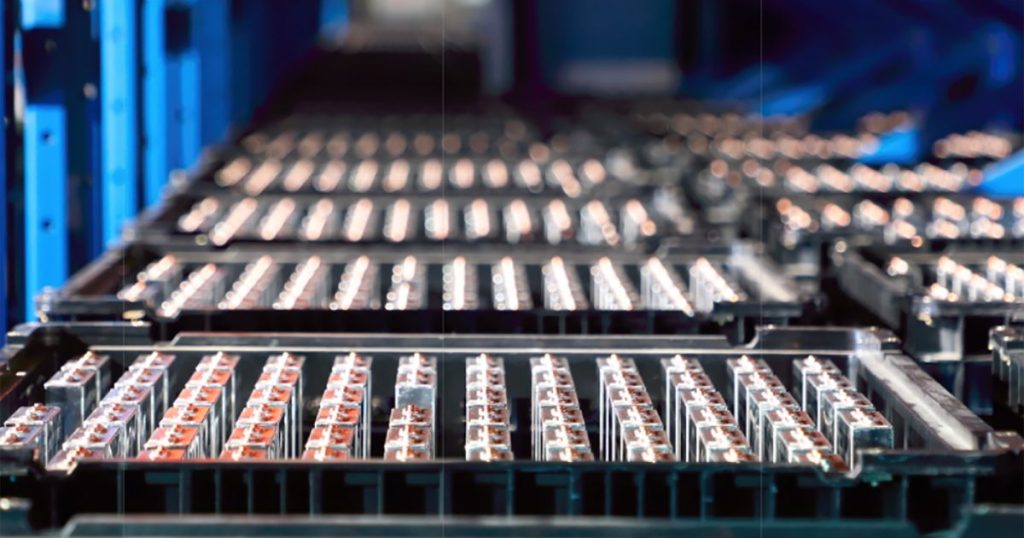

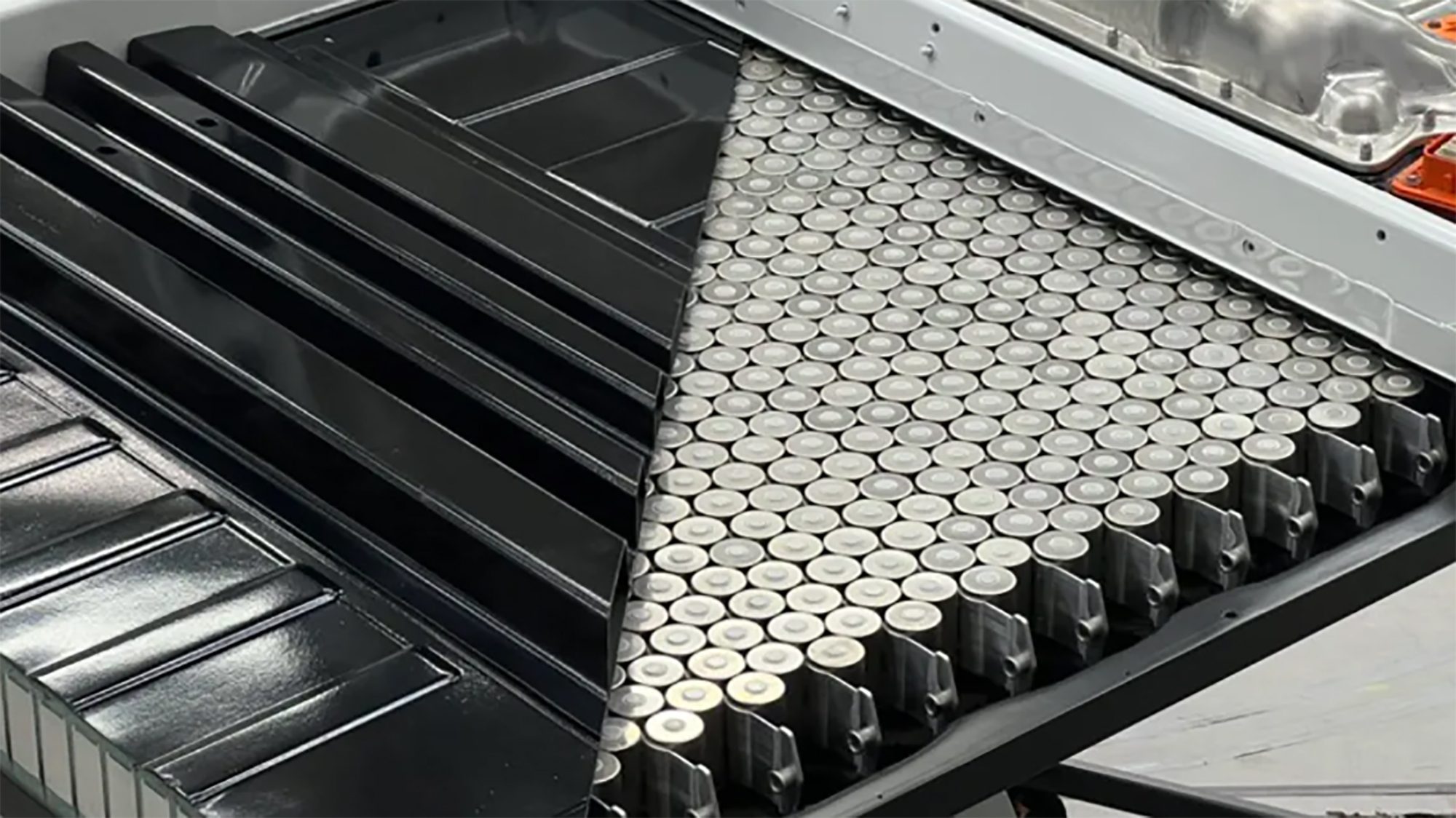

The big difference between an LFP battery and a regular lithium-ion battery (NCM/nickel-cobalt manganese or NCA/nickel-cobalt aluminum) is mainly in the chemical composition of the cathode. Instead of using metals like cobalt, nickel or manganese, we prefer iron.

So it is important to mention that LFP battery also contains lithium ions inside the electrolyte. In fact, except for the chemical composition of the cathode, the LFP battery functions exactly like a lithium-ion battery. Physically, she is almost identical.

Thus, in use, it is recharged in the same way and it gives the same kind of experience to its owner, this battery is continuously recharged up to 100% without showing signs of premature degradation, i.e. a loss of autonomy or a slowing down of the recharge rate.

What are the advantages and disadvantages of LFP battery?

Recharging to 100% is one of the main advantages of an LFP battery, as this practice does not cause premature degradation as in a lithium-ion battery. There’s also the fact that the LFP battery lasts longer over several recharge cycles. For example, long-life lithium-ion batteries can deliver 1,500 recharge cycles, while an LFP battery can reach 2,000 cycles.

It has a chemical composition that helps reduce reliance on controversial materials such as cobalt and nickel. Iron is easier to extract and therefore less polluting during its extraction, but also easier to recycle, which allows batteries to easily enter existing recycling processes. Then the cost of this metal is much lower and allows manufacturers to reduce their production costs when building the battery.

Does an LFP battery provide longer battery life than a lithium-ion battery?

On the other hand, the energy density of an LFP battery, i.e. its ability to store energy for a long period of time relative to its size (measured in watt-hours/kg), is significantly lower than that of nickel-based lithium-ion batteries. . For reference, the best lithium-ion batteries achieve an energy density of 325 watt-hours/kg. The LFP battery, meanwhile, currently tops out at 150 watt hours/kg.

However, this reality forces car manufacturers to make batteries with higher capacity to achieve the same range. The Tesla Model 3 is a perfect example. The old model had a lithium-ion battery with a capacity of 53 kilowatt hours, while the current model – equipped with an LFP battery – has increased its capacity to 60 kilowatt hours. Finally, due to its iron-based composition, the LFP battery is significantly heavier than a nickel-based lithium-ion battery, which helps increase the net mass of the vehicle.

However, recent advances in electric vehicle aerodynamics and energy management software, especially thanks to the help of artificial intelligence, allow automakers to overcome these problems. As proof, despite the battery with a lower energy density, Tesla still managed to get more autonomy from the Model 3, which allowed it to go from 400 to 438 kilometers.

More Stories

Sportswear: Lolle acquires Louis Garneau Sports

REM is still innovative enough to foot the bill

A trip to the restaurant with no regrets for these customers