Every Monday, we bring you a company that innovates.

innovation

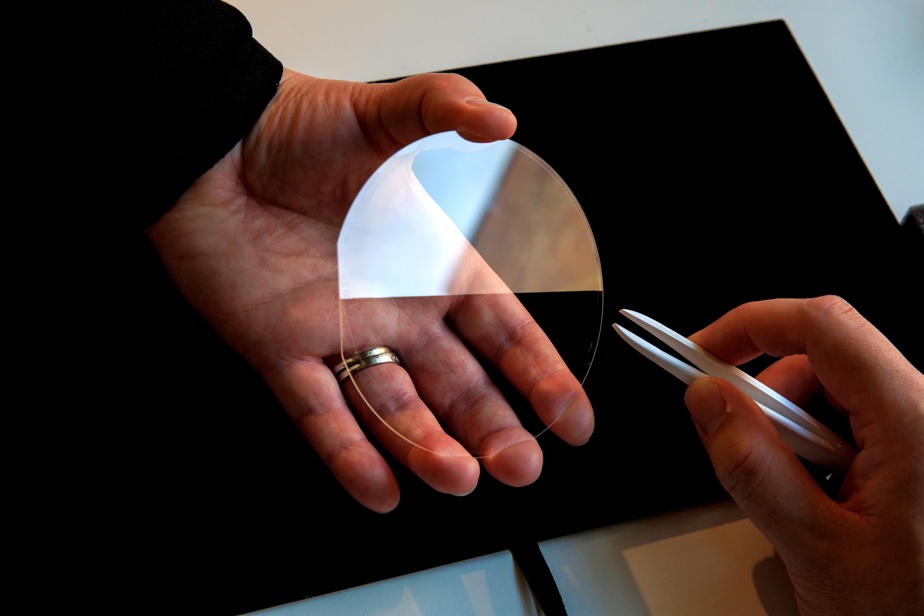

An anti-reflective treatment is applied directly to the glass, making it nearly 100% transparent and hydrophobic. In particular, it allows a 12% increase in the power output of solar panels and the elimination of glare in photography.

WHO?

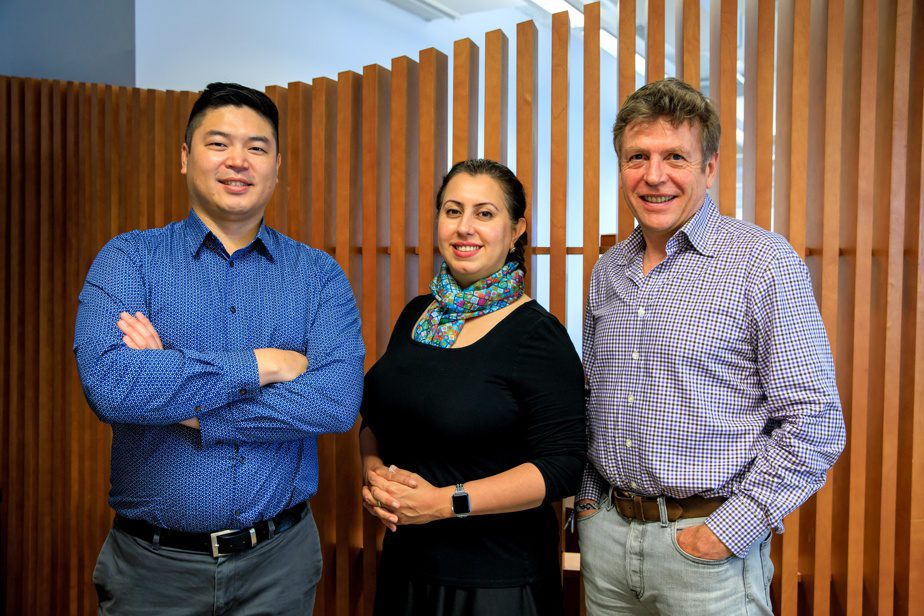

Teams from the United States National Laboratories conducted research for this technology nearly ten years ago. In 2018 Montreal incubator TandemLaunch acquired the rights and began the process of building a business around its operation. That year, we founded Edgehog (inspired by the English name for the hedgehog, Spiny Squirrel) with Calvin Cheng, Nasim Sahrai, and Siamak Kashi. The first is a doctorate in chemistry from the University of Toronto, the second is a doctorate in electrical and computer engineering from the National University of Singapore, and the third is a master’s degree from Polytechnique Montreal in engineering physics.

Photo by Alain Roberge, Pres

Calvin Cheng, Nassim Sahrai and Francois Jeaneau, the management team of EdgeHog, which markets a process that makes glass almost 100% transparent.

“The co-founding team didn’t know each other, we met through job offers and the TandemLaunch incubator,” explains Calvin Cheng, now EdgeHog’s COO. Mme Sahraï Product Manager and Mr. Kashi was director of processes and manufacturing until his departure last May. A fourth partner, François Jeanneau, became CEO.

EdgeHog employs about ten people at its offices on Peel Street in Montreal.

object

Conventional anti-reflective coatings add a layer of a specific material to the surface of the glass. The technology chosen and sold by EdgeHog alters the surface of the glass to create a layer that transfers light from the air to the glass. This creates these “shock” reflections of the passage between the two materials and the light partially bounces back.

“We were inspired by the moth’s eye (the moth in English), we call our technology “Moth-Eye 2.0,” Cheng said. This concept has been known for decades, only now have we harnessed this potential. »

After its treatment by Edgehog, the glass acquires almost complete transparency, which increases the flow of light through it. For a solar panel, this means an increase in energy production of 12% on an annual basis or more than 25% when the light strikes at an angle during sunrise and sunset.

Integrated into a camera or video camera, this glass reduces reflection and cancels halo effects. The treatment also makes the glass “superhydrophobic,” allowing it to be cleaned with water without droplets sticking to it.

“It works for all kinds of light and all angles,” says Cheng.

Edgehog has industrial customers for whom it processes glasses used in the composition of their products, particularly in aerospace and photography. No associated company name has been made public.

Challenges

The pandemic has been difficult for many companies, and especially for EdgeHog, which has not held back on telecommuting. “We’re a materials company, our work is physical,” says the operations director. Had to wait a few months. »

Photo by Alain Roberge, Pres

Calvin Cheng, COO of EdgeHog

Since we are dealing with companies and not consumers, Edgehog has to work within the time constraints imposed on him. “We work on their plan,” Mr. Cheng said.

the future

Edgehog doesn’t manufacture the glass components themselves, it converts them. “Our challenge is to increase our manufacturing capacity,” said the director. We use existing facilities, our challenge is to access larger equipment. »

Solar panels and photographic equipment are two areas where the need for anti-reflection technologies is most evident. “For a small company, we need to focus on these applications,” Cheng noted. As it matures, we will be able to enter new markets. »